We Design for the Future

We are wired for tomorrow

Magnetics

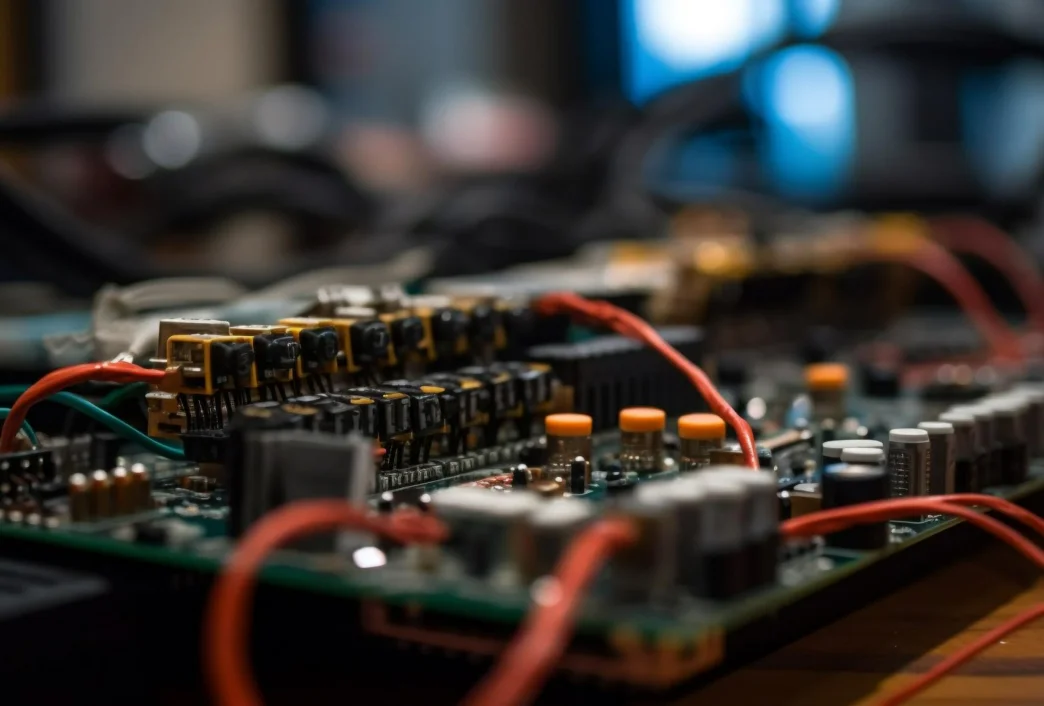

Syrma SGS Magnetics: Precision design & manufacturing

Our custom magnetic components are engineered for long-lasting, high performance.

With two decades of expertise, our skilled electronic engineers design and manufacture precision magnetic coils, inductors, transformers, and line filters optimized for reliability and efficiency.

We offer a broad spectrum of standard and application-specific components tailored to diverse markets and applications.

We support the full magnetic product development lifecycle from prototyping through high-volume production. Our OEM components are built to withstand extended use with minimal maintenance.

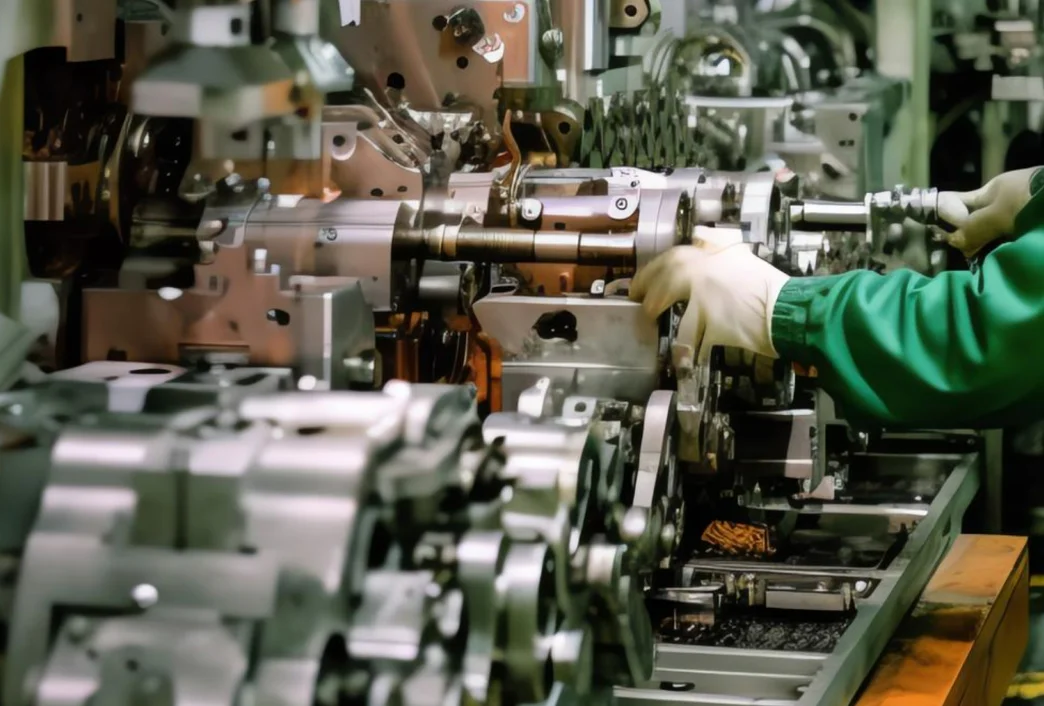

Our investments in next-generation assembly equipment and automated production lines allow us to optimize every build and provide customers with time and cost savings.

Industries

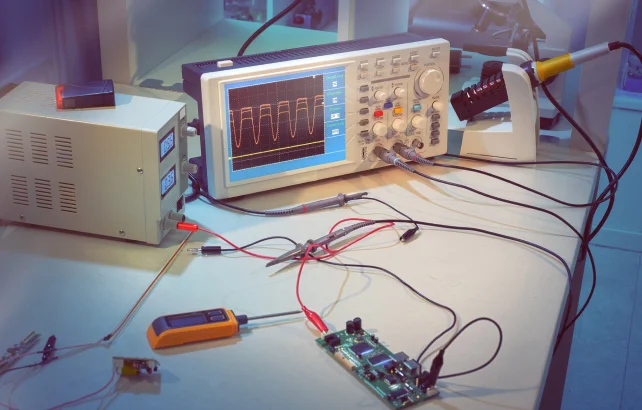

Test & Instrumentation

Telecommunications

Consumer Goods

Industrial Products

Factory Automation

Aerospace & Defense

Custom Magnetics Built for the Long Run

Syrma SGS custom magnetic components are engineered for long-lasting, high performance.

With two decades of expertise, our skilled electronic engineers design and manufacture precision magnetic coils, inductors, transformers, and line filters optimized for reliability and efficiency.

We support the full magnetic product lifecycle from prototyping through high-volume production. Our OEM components are built to withstand extended use with minimal maintenance.

We also provide value-added solutions like complete board and box builds for power electronics and assembled units.

With SyrmaSGS, you get more than just a manufacturer – you get a team dedicated to your product’s manufacturing success.

Capabilities

Expanding Capacity, Elevating Quality

SyrmaSGS has invested in advanced manufacturing technology and expanded capacity to efficiently deliver even your most complex electronics projects.

Our automated assembly lines handle large board sizes up to 500x450mm and diverse board materials including ceramic, flex, and rigid substrates. This enables us to meet the tightest tolerances and fulfill the most demanding build requirements.

Our state-of-the-art barcoding systems provide end-to-end traceability of each component and are integrated with ERP software to maximize productivity at every stage of assembly.

With capabilities like solder paste inspection, wave soldering, potting, conformal coating, back-end assembly, and testing, we can deliver complete assemblies from start to finish quickly and reliably.

Machines That Drive EMS Success

-

Board Size: Up to 534 x 610 mm

-

Board Types: Rigid, Flex, Ceramic

-

SMT assembly in class 10K & dust-free zone

-

N2 enabled reflow – JT, RW, Vitronic, Centuring

-

Wave Soldering – Tamura, Dektec

-

Automatic Conformal Coating & Potting

-

SPI – Cyber Optics & KY 3020T

-

3D & 2D AOI – Cyber Optics, Agilent & Viscom X-ray

-

ICT & MDA – Kyoritsu, SPEA, Tescon & TRI

-

FCT on LABVIEW SOFTWARE for every product

-

Post-Soldering AOI – TRI

-

Automatic Pin Insertion Machine

-

DFM analysis using Mentor Graphics

-

Barcode-based MES traceability system.

-

SMT

-

Throw hole assembly

-

Backend assembly

-

Testing

Component Engineering

-

Cross-referencing for cores and bobbins

-

Development of cores for better pricing. Wide range of core materials, such as soft ferrite, iron power, nanocrystalline, metallic glass, and KoolMu.

-

Develop bobbins constructed from thermoplastic or thermoset materials

-

Construction ranges from a few turns to a large number of turns with magnet, TIW, tefzel, and litz wires

-

Bobbin wound, torodial, SMT, and PTH

-

Automatic windings on bobbins

-

Development of other metal parts

Functional Testing

-

Inductance

-

Leakage and Inductance

-

Resistance

-

High-voltage test

-

Insulation resistance

-

Full visual inspection

Our Facilities

-

Manesar Unit 1 – 94,000 sq. ft

-

Chennai – Unit 2 – 30,000 sq. ft

-

Chennai – Unit 4 – 1,33,000 sq ft.

-

Info City, Gurgaon - 48,000 sq. ft.

-

Bawal – 40,000 sq. ft.

-

Bengaluru - 1,00,000 sq. ft.

-

Baddi – 32,500 sq. ft.

Our Expansive Reach

Customers catered across Automotive, Consumer Products, Healthcare, Industrial Appliances, IT and Railways during FY21

Countries where our products are sold

World class manufacturing facilities across India

Global and Indian suppliers during FY21

R&D facilities in Chennai, Gurgaon, Stuttgart, Germany

Whether you need rapid prototyping, low-volume batch production, or high-volume manufacturing, we have the technology, capacity, and expertise to handle your most intricate electronics projects.

Discover how we can help you launch a successful product.

Order Fulfilment & Strategic Sourcing

-

Ferrite: India – Epcos, MMG (Delta), Cosmo China – ACME, DMEGC, etc

-

Iron powder, Sendust, and Nanocrystalline cores from the USA and China

-

Toroid range upto 130mm Bobbins

-

Multiple global sources of wires.

-

Magnet wire from India, China and Taiwan • Magnet wire ranges from 0.035 to 3mm

-

Tex E/Tex FS wire from China and Taiwan • Tex-E wire range from 0.10mm to 1mm

-

Litz wire from India ,China and Taiwan

Quality Systems

Electrical Insulation System

-

Syrma’s Products are recognized under UL Insulation Systems

-

UL File No: E314308

-

Class 130 (B) coil and transformer insulation systems designated SY130 • Class 130 (B) coil and transformer insulation systems designated SY-130 • Class 155 (F) electrical insulation systems designated SY155

Conflict Minerals Compliance RoHS & REACH Compliance

Reliability Tests

-

Vibration test, Drop test, Humidity test, Temperature cycle test, Solderability test,

Discover the Syrma SGS Difference

Dedicated PM, NPI & Buyer for Large Customers

We provide dedicated Project Managers, New Product Introduction specialists, and Buyers for our large customers. Our experts fully understand your unique needs and ensure seamless execution from start to finish.

Key Performance Parameters Are Measured

We measure performance through key metrics like:

-

On-Time Delivery: We are committed to absolute timeliness in fulfilling orders.

-

Quality Yield: Rigorous quality control ensures we meet the highest standards with every product.

-

Customer Satisfaction Surveys: Regular surveys help us improve our services.

Fully Integrated Supply Chain for Sourcing

Our supply chain leverages integration and strong partnerships to enable efficiency, cost savings, and access to cutting-edge technologies and components. This gives you a competitive advantage.

Strong relationships with OEMs and Distributors

By nurturing relationships with OEMs and distributors, we stay abreast of the latest developments to procure the most effective technologies and components.

Geographical redundancy and Supplier Diversification

We mitigate risk through geographical redundancy across suppliers, ensuring supply chain resilience and continuity.

Safety Stock for Critical Sole Source/Single Definition Source Parts

Safety stock of sole source parts protects against disruptions to your supply chain when alternatives are limited.

Strong Local Supply Chain for Electro-Mechanicals

Our robust local supply chain for electro-mechanical components powers your operations smoothly.

Dedicated Focus on Commodity Development

We focus on advancing commodities and materials, giving you access to the latest innovations.

Our Products

Chokes

- High-current chokes for the welding industry

- Large-volume chokes for EMI/RFI Filter applications

- Bobbin wound, torodial, SMT, and PTH chokes

- 3-phase, epoxy-encapsulated, and toroidal core chokes

- Common Mode Chokes: Toroidal, Encapsulated & Ferrite Cores

Inductors

- Used in low-frequency power supplies as filter chokes, filter circuits, common mode chokes, noise suppression and high-frequency power supplies.

- Designed to operate over a wide range of frequencies, input voltages and inductance values.

- Can be varnish impregnated, molded, or potted with epoxy in an enclosure.

- Includes fixed, shielded and toroidal inductors, air core, powdered iron core, ferrite core, common mode, and power line chokes and filters

Induction Elements

- Custom-designed high efficiency coils for induction cooktops

- Different power ratings - 1200W, 1500W, 2200W, 3000W, 3700W • Different form factors – Circular, Oval, Double Coils

Transformers

- High current transformers rating up to 20KV

- Signal and impendence matching transformers

- Pot core/RM transformers

- Ferrite/ Iron powder/nanocrystalline E-core transformers (other geometries - EI/EF/ER/EFD/EP)

- High-frequency toroidal transformers