If the battery is the heart of an EV, then the Battery Management System is its brain. This is not just a statement; it is a foundational truth that lies behind the rapid acceleration of electric mobility. In 2024, EV global sales reached over 17.1 million units, which increased significantly by 25% year-over-year. This massive technological shift is breathtaking, where the performance, safety, and longevity of the EV are fundamentally enabled by BMS.

It’s critical intelligence that not only enables the growth of electric vehicles but also fundamentally safeguards the future of electric mobility. The continuous advancement of BMS is essential for the success of the EV revolution.

The Strategic Role of the Battery Management System

Battery Management System (BMS) is an electronic unit designed to monitor, control and optimize the performance of multi-cell lithium-ion battery packs. As a crucial component, BMS acts as the brain of a battery pack. It exclusively monitors temperature, voltage, and current to prevent overcharging, discharging, and overheating. By collecting and analyzing real-time critical data, it ensures energy usage and extended operational life.

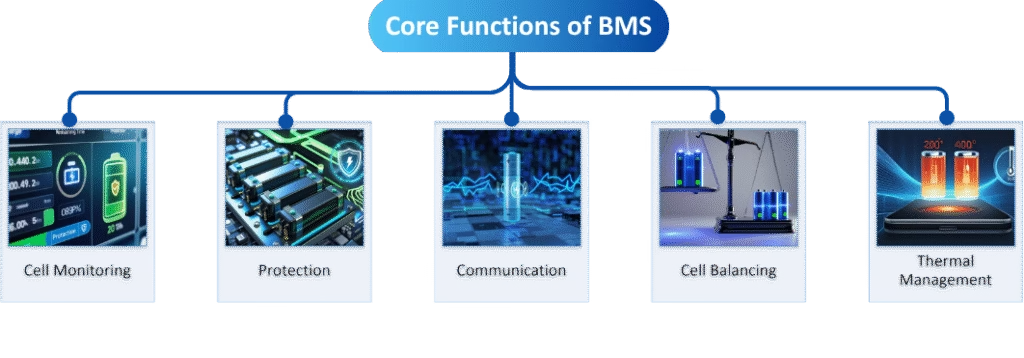

Core Functions of a BMS

BMS reliably performs a multitude of critical functions, each vital for the performance and safety of EV batteries. Let’s explore the core functions of a BMS and why it is indispensable to the EV ecosystem.

Cell Monitoring: It is a fundamental function that involves measuring real-time data like individual cell voltage, temperature, and current within the battery pack. Analog-to-Digital converters are employed to precisely estimate the tiny fluctuations in its power. For instance: An EV with a 400V battery pack contains hundreds of series-connected cells, BMS monitors each cell individually for deviations, which could be as small as 10-20 mV.

Protection: BMS initiates a protective mechanism in case of a detected fault. With immediate control of contactors and fuses, BMS disengages the battery pack from the vehicle’s electrical system and triggers visual/audio warnings to users. This response time will take utmost of 10 to 20 milliseconds to prevent catastrophic failures like thermal runaway.

Communication: BMS utilizes standardized protocols like CAN (Controller Area Network) to enable seamless communication with other vehicle control units (VCUs). Accessing real-time data like power delivery, charging status and battery status helps in efficient vehicle operation. The data set can range from 250 kbps to 1 mbps, based on system complexity.

Cell Balancing: Individual cells within a battery pack consistently show variations in voltage and capacity, meaning that they can’t behave identically. Such fluctuations can cause overcharging or deep discharging, which significantly shortens the overall battery life. Therefore, the cell balancing method is used to equalize the charge across all cells. In this mechanism, BMS implements both passive and active balancing.

- Passive Balancing—In this technique, the BMS discharges higher charged cells via a controlled resistive load. This converts their excess energy directly into a heat, resulting in energy loss but effectively equalizes their voltage with the rest of the pack.

- Active Balancing— Redistributes charge from higher-energy battery cells to lower ones to ensure the cells in a pack are equally charged.

Thermal Management—Temperature is a crucial factor that directly influences the battery performance and longevity. The BMS of electric vehicles constantly manages thermal performance with the help of an integrated heating and cooling system. The ideal temperature typically ranges from 20 to 40 °C for Li-ion batteries. A deviation of just 10 °C from this range can significantly affect the battery life by up to 50%.

How BMS Optimizes Every Mile

The Battery Management System (BMS) is not just for protection, it actively improves the battery performance, including safety, charging speed, and lifespan. It performs some significant roles like:

Maximizing Battery Life & Efficiency

BMS is a key factor to improve the battery lifespan and operational efficiency. It meticulously manages the cell voltage and thermal conditions within a specified range. Maintaining each cell voltage within a narrow, safe operating window (eg: 3.0v to 4.2v for Li-ion cell) contributes to a higher cycle life. Research indicates an effective thermal management system can reduce the capacity loss by 15 to 20% over 1,00,000 km of driving.

Ensuring Safety & Reliability

As a vehicle guardian, BMS acts as a safety shield by detecting and preventing thermal runaway. It will trigger a rapid, uncontrolled chain reaction that can lead to fire or explosion. To prevent uncontrolled exothermic reactions, BMS keeps an eye on temperature gradients and implements rapid fault detection. These multi-layered protection methods are closely aligned with automotive functional safety standards like ISO 26262 up to ASIL – D.

Optimizing Power Output & Performance

Beyond monitoring voltage and current, the BMS also estimates the remaining energy available for use. It also accurately provides the state of power (SoP), which means the maximum power that is available in a battery. Based on the battery’s internal resistance and available power, the acceleration and braking can be optimized. It manages the current flow back and improves vehicle efficiency by 10 to 15%.

Innovations in BMS Technology

The continuous innovation in BMS technology rapidly increases the demand for electric vehicles. Let’s explore some key innovations that efficiently shape the BMS technology:

Wireless BMS (wBMS) for Next-Gen EVs

EV users are experiencing significant transformation through Wireless Battery Management Systems (wBMS). By eliminating bulky and heavy wiring harnesses, wBMS promotes a lighter battery pack. This weight reduction alone potentially improves the vehicle range by 1 – 2% and reduces production time by 15 to 20%.

The flexible design minimizes the risk of failures associated with traditional wiring, such as corrosion or wire breakage.

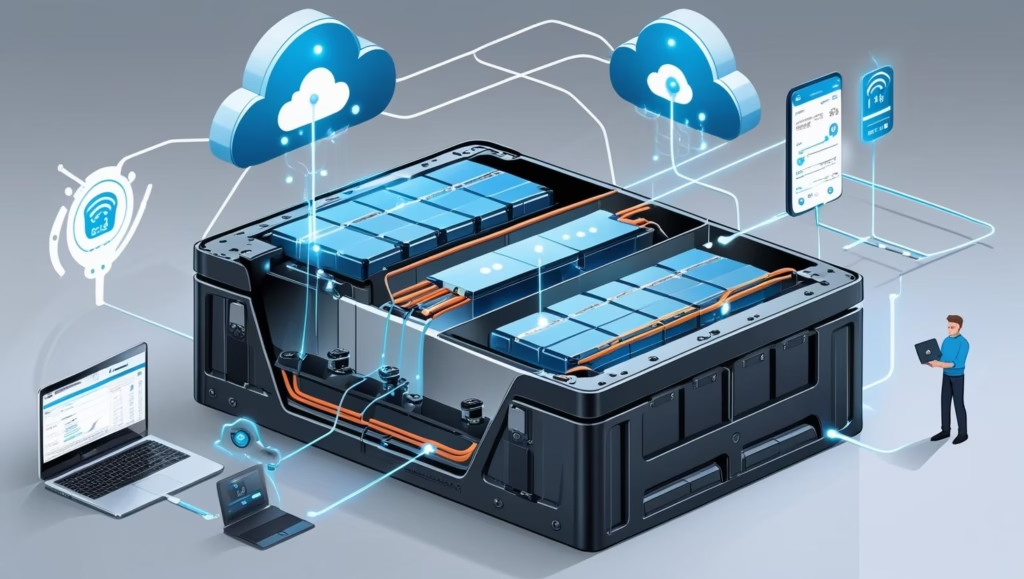

Integration with Vehicle IoT Systems

The integration of IoT systems (the Internet of Things) enables the BMS to connect with cloud platforms. This system is unlocking new possibilities such as remote diagnostics, over-the-air (OTA) updates, and predictive maintenance. In the case of repair, manufacturers and service centers can remotely access the battery and diagnose issues without a physical visit. The utilization of advanced machine learning algorithms can efficiently reduce the unexpected breakdowns by up to 30%.

Advanced Manufacturing & Development of BMS

The advanced optimization in BMS is expected to drive a significant transformation in its enhanced performance, safety, and cost-efficiency. This evolution is achieved through the following key aspects:

Modular and Scalable Architecture: BMS is moving towards modular and distributed architecture. Instead of a single central control unit, it is planned to design smaller, intelligent modules closer to every battery cell. It efficiently reduces the complexities and increases scalability in the assembly line.

Integration of ASICs and SoCs: BMS functionalities are increasingly benefited from the integration of ASICs (Application-specific integrated circuits) and SoC (System-on-Chip). ASICs are designed for specific BMS tasks, optimizing the overall component count and performance. However, the SoC integrates multiple complex functions onto a single chip. This includes memory, microcontrollers, and communication interfaces. Thus reducing the weight, cost, and physical size of the BMS, resulting in compact battery designs.

Automated Assembly and Testing: Automation enables scalable, error-free production of BMS units for modern EVs. It significantly reduces human error and increases manufacturing throughput. This system carries robotic assembly and sophisticated in-line testing.

BMS: Driving the Future of Electric Vehicles

BMS—the brain of the battery—is an undeniable truth. Its pioneering innovations such as wireless technology and the IoT integration enhance not only performance but also ensure its safety and reliability. Meanwhile, its design flexibility can efficiently manage the system’s unique characteristics like thermal properties, voltage windows, degradation mechanisms, etc.

However, navigating this critical technology demands a manufacturing partner with advanced production capabilities. We, Syrma SGS – a leading Electronic System Design and Manufacturing Company that offers end-to-end solutions for automotive electronics. Our expertise has proven capabilities in optimizing advanced BMS solutions that can power the next generation of electric vehicles and support a sustainable and electrified future.