Why Energy Efficiency Matters in Power Electronics?

As global energy demands surge and sustainability targets tighten, energy efficiency has become more than a design preference; It’s an engineering imperative. Every watt saved in conversion reduces generation needs across the energy chain, lowering operational costs and minimizing carbon footprints.

Power electronics, including converters and inverters, are critical to future energy systems and are key to system reliability and achieving global net-zero goals. This is especially true in industrial automation, electric vehicles, and consumer electronics, where power electronics are integral to new energy systems.

For manufacturers like Syrma SGS, energy-efficient design is a core philosophy, ensuring that every component delivers maximum performance with minimal waste.

The Physics Behind Efficiency: Core Principles at Work

Energy efficiency in power electronics depends on how effectively input power is converted into useful output while minimizing losses. The key metric conversion efficiency indicates the degree to which one form of electrical energy is converted into another. No system can achieve 100% efficiency since some part of the energy supplied to the system always escapes in the form of resistive, magnetic, or switching losses.

Power loss mainly occurs in two stages: conduction, where current flows through semiconductor devices, and switching, where devices transition between on and off states. These losses manifest as heat, which wastes energy and negatively affects device reliability and lifespan. Thus, dissipating heat is not only important in terms of system performance but also device reliability and lifetime.

The thermal effects of power loss introduce a complex interplay between electrical and thermal domains. Excessive junction temperatures can increase resistance, further reducing efficiency in a self-reinforcing cycle. Hence, thermal management through efficient heat sinks, advanced materials, and optimized layouts becomes an intrinsic part of the efficiency equation.

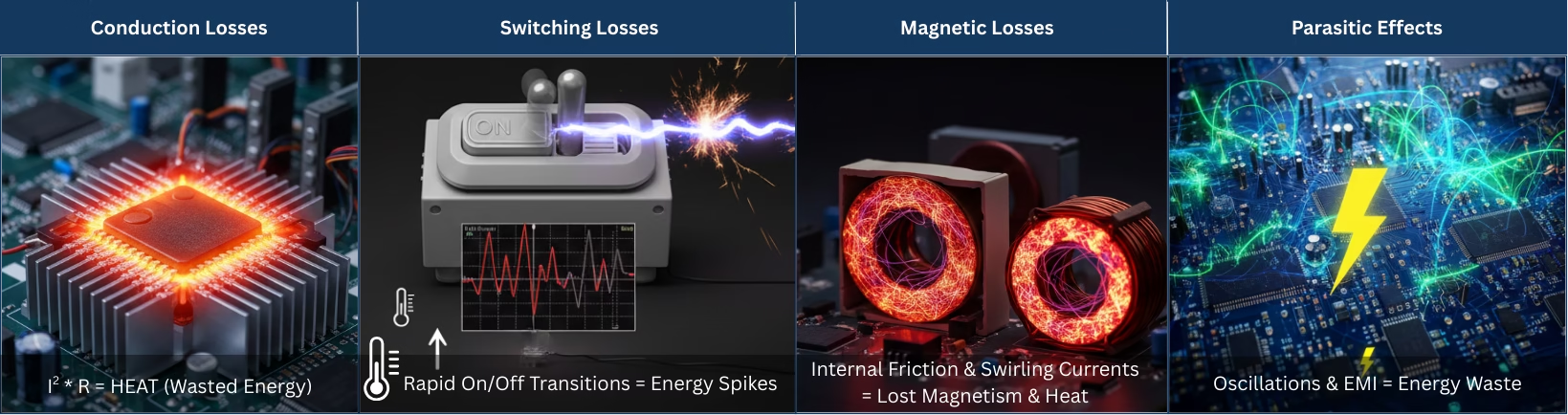

Where Energy Gets Lost: Understanding Efficiency Barriers

Energy losses in power electronics arise from several mechanisms that lower the efficiency figure.

- Conduction Losses: These arise when current passes through semiconductor devices like MOSFETs or IGBTs. The losses scale with current and device resistance, resulting in heat generation.

- Switching Losses: These occur when the device switches between on and off states, where voltage and current overlap, resulting in high switching losses. If the switching frequency is increased, these losses will also increase unless they are adequately cooled or limited.

- Magnetic Losses: These are losses in transformers and inductors caused by core hysteresis, eddy currents, and winding resistance. These factors reduce magnetic efficiency and increase the thermal load.

- Parasitic Effects: Parasitic inductance and capacitance are inevitable in the circuit that cause oscillations, ringing, and electromagnetic interference, leading to energy waste.

A well-engineered design minimizes losses through optimal device selection, efficient control algorithms, and precise PCB layout, ensuring higher energy efficiency and longer service life.

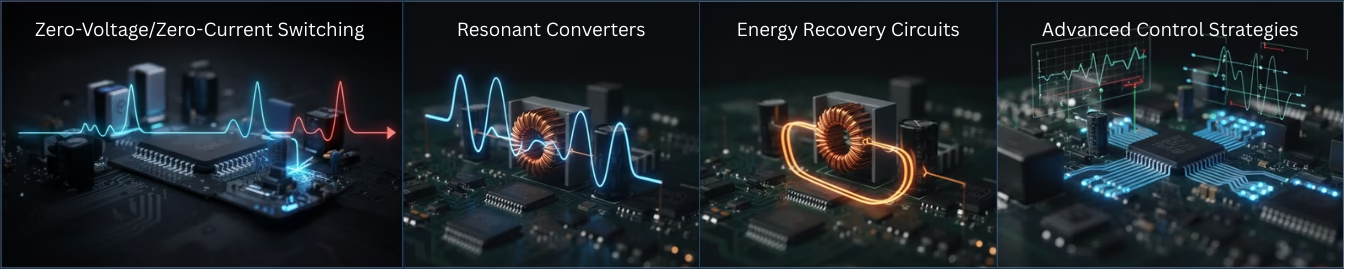

Design Smarter, Waste Less: Proven Techniques for High Efficiency

One of the main ways to improve energy efficiency in power electronics is by implementing innovative circuit topologies and using intelligent control methods that minimize losses without compromising device performance.

- Zero-voltage switching (ZVS) and zero-current switching (ZCS): Reduce switching losses by ensuring that the voltage or current is close to zero during the transition, thereby decreasing heat and extending device lifetime.

- Resonant Converters: Through the use of resonant tank circuits, they achieve natural soft switching. They operate efficiently across a wide load range, making them ideal for high-frequency power supplies and EV applications.

- Energy Recovery Circuits: They recover energy lost during switching or transient events, which is then used to power the rest of the system, increasing overall efficiency and reducing thermal stress.

- Advanced Control Strategies: Digital, adaptive, and predictive control algorithms dynamically adjust switching patterns and load conditions, enhancing efficiency and system reliability.

Choosing the Right Materials: Si vs. SiC vs. GaN

The foundation of energy-efficient power electronics lies in selecting the right semiconductor material. Each option, Silicon (Si), Silicon Carbide (SiC), and Gallium Nitride (GaN), brings distinct performance characteristics suited for specific applications.

Silicon (Si) is still the mainstay of the industry because of its longevity, low price, and readily available manufacturing ecosystem. It performs well in low- to medium-power scenarios such as industrial power supplies and consumer electronics. Nevertheless, the performance of silicon makes it less suitable for high-voltage, high-frequency applications.

Silicon Carbide (SiC) components offer a superior voltage handling capability, lower losses, and a higher thermal tolerance; hence, they become the first choice for electric vehicles (EVs), renewable energy inverters, and high-power industrial drives. In addition, SiC’s feature of high-temperature operation has the benefit of less cooling and more reliable systems.

Gallium Nitride (GaN) pushes the boundaries of efficiency by providing even faster switching speeds and enabling higher efficiencies. The low parasitic capacitance of GaN enables very compact, lightweight designs for fast chargers, telecom, aerospace, and data center applications. Though costlier, GaN delivers exceptional power density and energy savings.

The choice between Si, SiC, or GaN depends on efficiency targets, voltage, heat constraints, and budget, guiding engineers toward intelligent and eco-friendly power solutions.

Keeping It Cool: Thermal Management for Sustainable Design

Effective thermal management is essential for achieving energy efficiency and system longevity in power electronics. As devices handle higher power densities, excess heat can degrade performance, shorten component lifespans, and reduce overall reliability. Sustainable design requires an integrated approach addressing heat generation, transfer, and dissipation from the start.

Key Thermal Management Strategies

- Optimized PCB Design: Maintains uniform heat distribution using copper pours and thermal vias.

- Advanced Materials: Implements high-conductivity substrates and thermal interface materials (TIMs).

- Efficient Cooling Systems: Use of heat sinks, vapor chambers, and liquid cooling for effective heat dissipation.

- Real-Time Monitoring: Sensors enable dynamic thermal control and predictive maintenance.

- Material Innovation: Transition to SiC and GaN devices that generate less heat at the semiconductor level.

Blueprint of Efficiency: Smarter Circuit & PCB Design

A PCB layout significantly influences the behavior of the system regarding electromagnetic compatibility (EMC), signal integrity, and loss distribution. High-efficiency layouts employ:

- Foundation of Efficiency: In power electronics, the PCB design plays a major role in energy conversion, heat management, and overall system reliability. More intelligent layouts can convert just electrical precision into real efficiency gains.

- Optimized Power Paths: Employ short, wide traces along with thicker copper layers to do away with resistive losses and voltage drops. Multi-layer boards can thus separate power and signal paths efficiently.

- Strategic Component Placement: Place switching devices, drivers, and capacitors in such a way that they are close together to reduce parasitic inductance and noise to a minimum level. Ensure sensitive analog circuits are isolated from high-power zones.

- Controlled Parasitics & Noise: Introducing measures like short gate loops, Kelvin connections, and snubber circuits helps limit switching losses, ringing, and EMI issues.

- Robust Grounding & Return Paths: Strong ground planes and low-impedance return paths improve signal integrity and stabilize high-current paths.

- Thermal Management: Using thermal vias, copper pours, and heat-spreading patterns helps manage temperature rise and ensures long-term stability.

- Simulation-Driven Design: Power, thermal, and EMI simulations serve the purpose of design validation at an early stage, reducing prototyping cycles and improving design quality.

Trends Shaping Tomorrow: Innovations in Efficiency

The future of power electronics is being redefined by innovations that push the limits of energy efficiency. Wide-bandgap semiconductors such as SiC and GaN are enabling higher switching frequencies, reduced losses, and more compact systems.

AI-driven design optimization is streamlining circuit modeling and predictive control for superior performance. Integrated power modules are enhancing thermal management and reliability, supporting miniaturization without compromising output.

Additionally, the rise of digital twin simulations allows engineers to test and refine efficiency in real time. As sustainability takes center stage, the adoption of eco-friendly materials and recyclable components is accelerating.

Together, these advancements are shaping a new generation of intelligent, energy-efficient power systems built for a sustainable future.

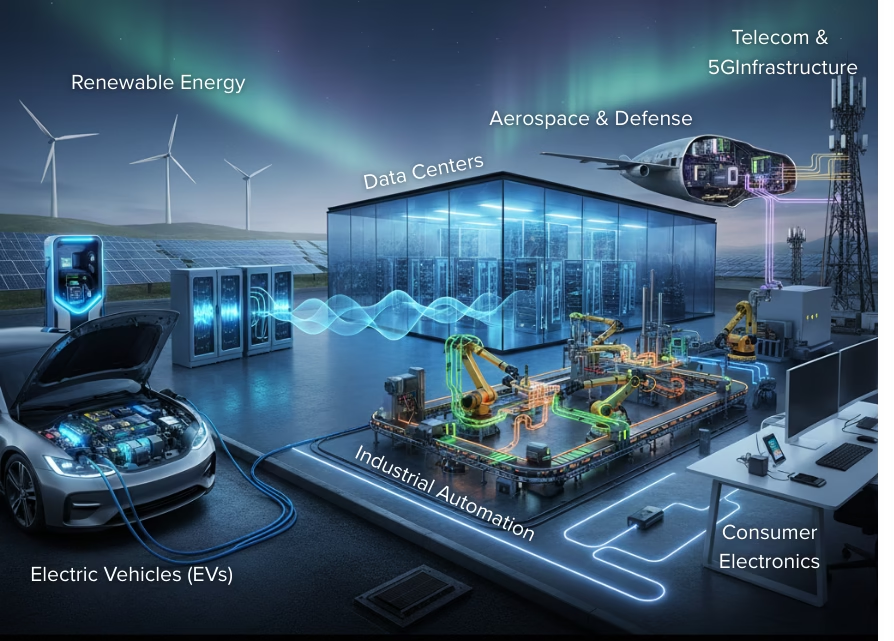

Real-World Wins: Applications & Industry Impact

Electric Vehicles (EVs): High-efficiency converters based on SiC and GaN lead to a better powertrain performance, thus a longer battery range, and with lower heat generation, enable ultra-fast charging.

Renewable Energy Systems: The use of advanced inverters with an optimized switching pattern leads to minimizing energy losses in solar and wind applications, improves grid stability, and maximizes renewable output.

Data Centers: The use of energy-efficient power supplies and cooling systems is resulting in lower operational costs and fewer carbon emissions, which is the prerequisite for a clean, high-performance computing environment.

Industrial Automation: Efficient motor drives and intelligent controls power robotics and production lines, saving energy while increasing productivity and sustainability.

Aerospace & Defense: Lightweight, high-density power modules provide reliable power in mission-critical, extreme conditions.

Consumer Electronics: Small GaN chargers and smart adapters offer faster charging as well as reduced heat generation, making them excellent examples of energy efficiency in everyday use.

Telecom & 5G Infrastructure: Effective power amplifiers and rectifiers are a means to network uptime extension, with reduced total energy consumption as an added advantage.

Towards a Sustainable Power Electronics Era

The transition to sustainable power electronics marks a defining moment in modern engineering. With the global trends of electrification and digitalization of industries, it is evident that efficiency, material innovation, and thermal intelligence are becoming the main pillars of a responsible design.

Systems with smaller environmental footprints—enabled by wide-bandgap semiconductors, intelligent controls, and recyclable materials achieve higher performance.

The next generation of power electronics is all about holistic design, figuring out how to use every watt, component, and circuit for durability and eco-friendliness.

The Takeaway: Designing for a Smarter Energy Future

Energy-efficient design is no longer a matter of making small changes; it is essentially about redefining how energy systems are created and maintained. A smarter energy design requires a single integrated approach combining advanced materials, intelligent control, and optimized thermal and circuit architectures.

Every design decision from semiconductor choosing to PCB layout has a role in cutting losses, increasing reliability, and lengthening product life. Electrification and digitalization of industries should prioritize sustainable performance, not just raw performance.

At Syrma SGS, we champion this mindset by embedding efficiency into every stage from concept to production, ensuring our solutions deliver higher reliability, lower energy consumption, and reduced environmental impact. By prioritizing smarter, cleaner designs today, we pave the way for a more resilient and energy-responsible tomorrow.

Disclaimer: Images used in this Blog are AI generated