Robotics in Machine Vision: How Automation Learns to See the World

Seeing has become as important as moving for automated systems in the current manufacturing industry. Previously, the automation would just follow the same fixed instructions every time but the factories today are surrounded by the variations of different part sizes, changing materials, and new product designs. This is how machine vision has emerged as a necessity. It provides the system with the ability to grab and understand the visual data so that they can recognize the components, check the quality, and detect the faults at the same time.

However, vision alone has limitations. A camera can identify the problem but it will be helpless in solving it. And that is what makes robotics in machine vision highly effective. With the help of robotics, vision systems not only see but get the capability to physically perform the actions.

Combined, vision and robotics are able to generate a closed-loop of intelligence. Machines have gone far beyond the stage of simply checking; they can now comprehend and react. Being able to see, decide, and act within milliseconds is what makes the modern-day automation faster, more precise, and genuinely smart.

Machine Vision–Powered Robotics in Industrial Automation

Machine vision came into the manufacturing world as a digital eye. Initially, it was intended to capture images, measure dimensions, and determine if the parts matched the criteria set. They were very capable of spotting when pieces were defective, wrongly aligned, or components that were missing, yet they couldn’t do anything physically. When the problem was found, an operator had to come and fix it thus causing delay and a chance of error.

The major discovery happened when machine vision was combined with robotics. Robotics bridged the gap between seeing and doing. So if the vision system detects the object’s position, orientation, or condition, the robot would be able to react immediately, either giving the part, removing it, or changing the part without human intervention. This type of automation system changed from one that only inspected to one that did production with active self-correction.

Today, the interaction between the two enables robots to work with irregularities in size, shape, and location without stopping the conveyor. Robots equipped with vision technology can continue to adjust, allowing them to manufacture even complex, high-mix products.

The combination of their visual capability and physical movement makes it possible for factories to function at a higher speed, with a greater level of accuracy, and a significantly lower number of defects—thereby paving the way for truly intelligent automation.

The Quiet Revolution on the Factory Floor

Nowadays, a quiet yet deep change is happening at the factory floors of electronics and components manufacturing. Robots equipped with vision, completely leaving their restriction to simple, repetitive movements, are now able to recognize, analyze, and decide- all happening at the same time.

In high-speed PCB assembly, cameras capture images of soldering joints, component positioning, and micro-level defects while robotic arms play the role of resuming placement within the blink of an eye. The result is no need for manual rework, and every board just about meets quality standards. Machine vision turns the work of semiconductor packaging robots into a chore of extreme care picking,’ the frail chips with micron-level accuracy, thus damages and losses are kept at the lowest possible levels.

Speed and consistency are only two of the elements that make this transformation very powerful. Vision systems are designed to take thousands of pictures per second. AI-powered models can identify patterns, changes, and flaws in the sensory data.

These robots can instantaneously do one of the following: reject a part, reposition it, or make a correction without interruption of the line. The manufacturers can run faster, leaner, and more reliably than ever before, thanks to this efficient cycle of seeing → deciding → acting. Instead of continuously doing repetitive tasks, human inspectors were freed up for process enhancement and quality planning, which require high-level thinking.

How Robotics and Machine Vision Actually Work Together?

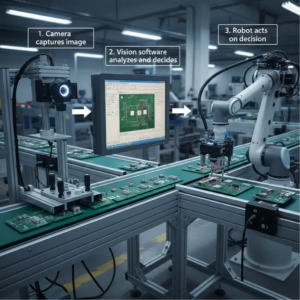

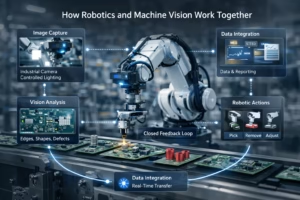

Machine vision in robotics essentially makes a closed-loop system whereby machines are not just able to see, but also comprehend and react in real time.

At first, image capture is made by industrial cameras and controlled lighting that gather accurate visual data of the parts, assemblies, and surfaces of the products on the assembly line. Afterwards, vision software analyzes these images in order to find out the edges, shapes, locations, defects, and barcodes, thus changing raw pixels into valuable manufacturing data.

Furthermore, AI and deep learning techniques add to this stage by diagnosing patterns, natural variations, and defects that traditional rule-based systems normally overlook.Data integration transfers this visual intelligence to the robot controller instantaneously, thus a closed feedback loop between seeing and doing is established.

Robotic systems interpret this input to direct movement, thus enabling the robot to carry out a set of accurate functions such as picking, placing, aligning, and inspecting, even if the parts have some variations. In addition, control algorithms continually fine-tune robot trajectories by utilizing live visual feedback, thus accomplishing precision at high speeds. Besides, manufacturing execution systems (MES) are used to store vision and robot data for solvency, quality reporting, and process optimization.

In addition to all these, scalable architecture assists the factories to put more cameras, robots or AI models for the production complexity increase.

Beyond Detection: Letting Robots Interpret the Physical World

Traditional machine vision systems were designed to detect predefined defects, relying on fixed rules and threshold values. While effective, they struggled when products, materials, or conditions changed. AI-driven vision changes this limitation by enabling robots to interpret what they see rather than simply match it against a checklist.

With deep learning models trained on thousands of real production images, robots can now recognize complex patterns, subtle surface variations, and anomalies that would be invisible to conventional systems. They learn what “normal” looks like and identify deviations—even those that were never explicitly programmed. This makes it possible to catch early-stage defects, material inconsistencies, and process drift before they turn into costly failures.

By combining AI vision with robotic motion, factories gain adaptive systems that improve with experience. The result is smarter inspection, higher quality, and more resilient automation across fast-changing manufacturing environments.

Where Robotics and Vision Prove Their Real Value on the Factory Floor

On the production lines of today, which change very fast, we can hardly observe the power of robotics in machine vision from simply theoretical aspects at first. It is revealed deeply in daily operational impact.

- Vision-guided robots can identify and pick out parts that are randomly oriented in a bin, in this way they can eliminate manual sorting and reduce the production cycle time on production lines with many different kinds of products.

- Cameras can be used to check the position of micro-level parts in an electronics assembly and simultaneously, robots can make real-time adjustments in the alignment thereby, solder quality is kept consistent.

- Automated optical inspection combined with robotic handling removes defective units instantly without stopping the line.

- During packaging, vision systems verify printed barcodes, labels, and sealed packages, then robots automatically rework any misfits with the product without stopping the production line.

- Vision system enabled co-bots help operators by recognizing situations not safe for humans and if it detects such, it co-interacts with the operator by slowing down or changing its path.

- Surface finishing robots use vision to detect scratches, dents, or coating imperfections and deliver on targeted rework.

- Again, autonomous material handling robots make use of visual clues much more than using certain designated routes in busy factory layouts to move around and perform the tasks.

- For traceability, serial numbers can be captured by vision systems while robots can direct the flow of products to the correct production or testing stations.

Managing Variability on Factory Floor with Robotics & Machine Vision

Variability is inherent in any manufacturing process, especially in today’s fast-changing environment. Components always have slight differences, materials may vary, and production conditions may change. The robotics equipped with vision systems help to overcome these challenges and even turn variability into precision.

- Real-Time Visual Analysis: High-speed industrial cameras capture images of the units from all angles, determining their positions and orientations. Thus, robots act based on real conditions instead of fixed coordinates.

- Adaptive Motion Control: In response to a sensed change, a robot modifies its motion instantly without any human intervention. It can do so while maintaining its accuracy and speed.

- Defect Detection and Correction: With the help of an integrated camera, the robot can perform on-the-fly inspections and identify defects, eliminating the parts or reworking them without human intervention. Furthermore, it can automatically position components.

- Flexible Mixed-Product Handling: A robot is able to work in a factory that produces several different product lines with the capability of adjusting to changes in size, shape, and configuration.

- Continuous Learning: With the help of AI, vision technology enables robots to enhance their abilities in recognition and response to fewer reprogramming’s while solving new tasks.

By integrating visual sensing and execution, machine vision robotics enables factories to achieve higher productivity through less downtime, lower use of materials, and stable output quality, even when the production is very diverse.

Advancing Robotics with Vision for Better Accuracy and Control

Robots with vision capabilities that are built nowadays do not only perform tasks that are preprogrammed, they also see, understand, and react to changing conditions in the environment around them at the same time. The combination of ultra-high-resolution cameras, AI-based image analysis, and extremely precise robotic actuators enables factories to reach levels of accuracy that have never been seen before, to find the defects earlier, and to react on the spot to the variation on the production line.

Such a change not only leads to improved efficiency but also to smart decision-making through which predictive maintenance, adaptive workflows, and intelligent quality control can be implemented. In the future, as sensors get smarter and AI models become more advanced, factories will be able to control everything more closely, thereby creating self-optimizing, flexible production systems. Robotics with vision is the roadmap to the factories of the future.

A Future Built on Clearer Vision and Smarter Motion

The convergence of robotics and machine vision is redefining the factory floor. Robots no longer just follow instructions; instead, they see, interpret, and act, adapting to variability and driving consistent quality at speed.

From electronics assembly to precision inspection, this synergy elevates manufacturing intelligence, reduces errors, and accelerates throughput. Factories that embrace this integration gain not just efficiency, but the ability to evolve with changing demands.

At Syrma SGS, we help businesses implement cutting-edge vision-driven robotics solutions that turn insight into action, ensuring smarter, faster, and more resilient operations.

Disclaimer: Images used in this Blog are AI generated