In high-volume manufacturing, moulds are the backbone of production. Choosing the right mould at the right time ensures quality, efficiency, and safety. Earlier, mould identification was done manually by checking barcodes, engraved numbers, or markings. In these processes, it would lead to misidentification, human errors, and time-consuming tracking.

These bottlenecks have been overcome by employing RFID (Radio Frequency Identification). RFID-enabled automated, accurate, and real-time tracking of moulds has ensured smooth operations, reduced downtime, and ensured the reliability of mould management. It’s becoming an essential tool for industries where precision and efficiency define competitiveness.

How is RFID applied in Mould Identification and Tracking?

RFID makes mould identification simple, accurate, and automated. The mould is installed with an RFID tag containing the identity number and required production information. As the mould moves across the shop floor, RFID readers automatically capture this information and sync it with a central system.

This process enables manufacturers to:

- Verify the correct mould instantaneously before production begins

- Track the movement and location of any mould in real time

- Use history for planning maintenance

- Avoid any downtime caused by manual errors or the misplacement of moulds

Basically, RFID provides full visibility and control over the mould lifecycle, helping maintain product quality and operational efficiency.

RFID in Tyre Manufacturing

The tyre industry is one of the best examples of how RFID transforms mould management. Here’s how the workflow looks:

- Tagging the Moulds- Each tyre mould now has an RFID tag. Such tags have to be rugged enough to withstand very high temperatures, pressure, and interference from metal.

- Automatic Identification- Moulds are configured with curing presses or other production stages, and fixed RFID readers capture their details without requiring manual scanning.

- System Integration- The data then flows into the manufacturing system, which instantly validates the mould in use and updates its real-time status.

- Monitoring Life Cycle- The system logs each cycle, tracks the mould usage hours, and triggers an alert when the maintenance or replacement of the mould is due.

- Full Traceability- Every tyre produced can be traced back to the mould used, and this is invaluable during quality audits, recalls, and compliance.

In Syrma SGS, we develop customized RFID solutions aimed at high-volume industries such as tyre manufacturing. Our testing for RFID tags involves surviving harsh environments and metal-heavy conditions, while we are also skilled systems integrators who connect them with ERP, MES, and other factory systems. Provides tyre manufacturers with complete mould visibility throughout the manufacturing cycle, improving efficiency and reducing operational risks.

Technical Implementation Details

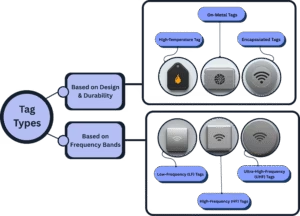

Depending on the environment, appropriate tags and readers must be chosen to reliably identify the mould, especially for tyre or automotive manufacturing. The tags must withstand heat, metal interference, pressure, and dust or chemical exposure. The best choices are:

- High-Temperature Tags– Designed to survive curing and heating.

- On-Metal Tags– Promised to perform accurately when mounted on moulds and other metals.

- Encapsulated Tags– Sealed for durability against dust, oil, and chemical attacks in factory ambient air.

While various uses are catered for in the different frequency bands:

- Low-Frequency (LF) Tags– Short reading range, highly effective near metal and liquids.

- High-Frequency (HF) Tags– Reliable read at the middle range; industrial application for mould tracks.

- Ultra-High-Frequency (UHF) Tags– The long read-distance ones, highly effective near metal and liquids

We at Syrma SGS design and manufacture a wide range of RFID tags and inlays catering to various industrial requirements. Our expertise also includes;

- Customizing tags for high-temperature and metal-heavy conditions

- Developing rugged designs for extended lifecycle performance

- Providing end-to-end solutions from RFID hardware to system integration

This ensures that manufacturers achieve consistent, accurate, and future-ready mould tracking systems.

Challenges in Mould Identification

RFID brings automation and accuracy to mould tracking; however, application in some industrialized environments isn’t without hurdles. This can be grouped into environmental, implementation, and operational factors.

Environmental Challenges

- Metal Interference- Moulds are usually made of metal, block, or reflect RFID signals, resulting in missed reads. Specialized “on-metal” tags reduce this issue, but at a higher cost.

- Extreme Heat- During injection and curing processes, moulds face temperatures between 150 and 300~°C, which would destroy almost any other RFID chip. Only heat-resistant tags can survive this extreme.

- Pressure and Chemicals- Extremely high moulding pressures, oil, and chemical cleaners demand tags with a rugged chemical resistance.

- Physical Wear- Frequent handling, movement, and cleaning may cause scratches on tags, which may then detach or get damaged.

Implementation Challenges

- High Cost– Rugged, heatproof tags and supporting infrastructure cost significantly more than standard RFID or barcode systems.

- System Complexity– Installing RFID requires site surveys, strategic reader placement, and calibration to avoid interference.

- ERP/MES Integration– RFID has to be integrated with the enterprise system to ensure accurate data flow.

- Resistance to Change– Employees accustomed to manual methods may resist adoption

Operational and Data Challenges

- Tag Collision– In cases where many moulds are scanned simultaneously, a poorly designed system will cause data collision errors.

- Data Overload– RFID generates volumes of data that must be sifted and transformed into actionable insights.

- Scalability– Making RFID available in multiple plants requires the same infrastructure and data standards.

Benefits of RFID in Mould Identification

RFID brings intelligence to mould management by assigning each mould a digital identity. Traditional techniques are often rife with errors, are delayed, and lack any visibility. RFID negates these issues by assigning each mould a digital identity that enables real-time tracking, automated maintenance alerts, and error-free transactions.

If implemented correctly, RFID offers several benefits for high-volume industries such as automotive, plastics, and tyre manufacturing:

- Error-Free Operations- The tag contains a unique ID and data specific to the process. An alert is raised if the wrong mould is introduced or paired to equipment, and this avoids costly rejects.

- Safer Work Environment- RFID systems track mould handling via cranes and forklifts to prevent mishandling or accidents.

- Reduced Downtime- Automatic monitoring of wear and usage of moulds allows the planning of maintenance in due course to avert unexpected failures.

- Long Life of Moulds- Optimized through real-time tracking of pressure, temperature, and usage, extending mould life by 20–30%.

- Maintenance Intelligence- RFID tags store service histories, creating a digital health record that helps predict potential issues and prevent duplicate work.

- Real-Time- Readers positioned across the facility provide live mould location updates, preventing loss or misplacement.

- Smart Inventory Control- Immediate awareness of the status of moulds that are unused or missing enhances audit accuracy.

- Fewer Errors and Costs- Automatically capturing data reduces the need for manual intervention and consequently reduces errors and labor costs.

- Higher Quality Output- The elimination of mismatched moulds, along with the improved process control, will significantly cut down defect rates.

- Production Planning Optimization- Seamless MES/ERP integration supplies invaluable data on material sourcing and scheduling decisions.

- Considerable Cost Savings- The savings will be quantifiable through less scrap, fewer reworks, longer mould life, and increased productivity.

- Easy to Integrate- RFID can be retrofitted to existing moulds and management systems with minimal disruption.

Future of RFID in Mould Tracking

The future of RFID in mould management strongly leans toward integration with IoT, AI, and automation to create smart, connected mould ecosystems. Industrial-grade RFID tags will be digital IDs, which store history and allow real-time cycle count, temperature, and location tracking. When combined with IoT sensors, moulds turn into fully traceable assets across production, storage, and maintenance.

The power of AI in the predictive realm will mean giving intelligence to forecast wear of a mould, optimize process parameters, and hence, enhance maintenance activities to reduce downtime. Machine learning and AI-enabled vision systems will also enhance quality control and reduce waste. Automating mould verification, digital twin simulation, and supply chain integration will make RFID the central pillar for smart, lean, and Industry 4.0-ready manufacturing.

Conclusion

Effective mould identification is critical for efficiency, quality, and traceability in high-volume manufacturing. Traditional methods often fall short, but RFID delivers real-time visibility, predictive maintenance, and complete lifecycle tracking. As industries move toward smarter, automated operations, RFID will play a central role in enabling reliable and future-ready mould management.

At Syrma SGS, we offer custom RFID solutions tailored for industrial environments, helping manufacturers achieve higher productivity, reduced downtime, and long-term cost savings.

Disclaimer: Images used in this Blog are AI generated