In today’s smart world, safety often relies on hidden technologies like IR Reflectance Alarms. These invisible guardians use infrared light to accurately detect presence, motion, or distance, ensuring smooth and secure operations across industries — from factory floors to medical devices.

This helps prevent accidents before they happen. In our connected world, innovation is key. IR Reflectance Alarms show that the best protectors often work quietly. They safeguard lives, assets, and systems with precision.

Guardians You Can’t See but Can Trust

Infrared (IR) Reflectance Alarms are perfect examples of unseen protectors. These alarms protect people, processes, and machines with remarkable accuracy. Using infrared light, they detect presence, motion, and distance without physical contact.

IR Reflectance Alarms send out an infrared beam to a surface and measure the reflected light. When something enters the detection field, it changes the reflection pattern. This triggers an alert. These devices stand out from traditional sensors. They don’t rely on visible light and don’t need contact. This makes them great for dark, dusty, or complex environments. So, they are dependable in many industries.

The role of these silent guardians is vital. They prevent collisions, improve efficiency, and lower human risk. Their compact, contactless design works well in industrial automation, robotics, smart security, and healthcare. IR Reflectance Alarms offer speed, accuracy, and durability. They offer invisible but reliable safety. This ensures seamless protection in smart, connected spaces.

The Science of Light and Shadow: How IR Reflectance Alarms “See”

At the core of an IR Reflectance Alarm is the interaction between infrared light and reflective surfaces. This enables the device to detect objects, motion, and proximity without any contact. Unlike visible light sensors, IR sensors work in a spectrum that humans cannot see. This gives them precision and discretion in monitoring.

- Emission of Infrared Light

The process starts with an IR emitter, typically an infrared LED. It sends a focused beam of light to a target surface.Infrared light remains unaffected by visible light, ensuring reliable performance in both bright daylight and total darkness

- Interaction with Surfaces

When the IR beam encounters an object or surface, a portion of the light is reflected toward the sensor. Reflection significantly depends on surface features like color, texture, and distance. Dark or matte surfaces reflect less light, while bright or glossy surfaces reflect more.

- Detection of Reflected Light

A photodetector, such as a photodiode, captures the reflected light and converts it into an electrical signal proportional to the light’s intensity — a more reflective surface produces a stronger signal.

- Signal Processing and Thresholding

The electrical signal from the photodetector is then processed by a signal processor or microcontroller. Variations in the signal indicate the presence, absence, or movement of objects, thereby triggering the alarm.

- Noise Reduction and Accuracy

Environmental light interference is reduced using optical filters and modulated IR signals, resulting in high accuracy and minimal false alarms.

- Practical Implications

This science of light reflection enables IR Reflectance Alarms to “see” objects without audible or visible signals. They can detect fast-moving objects, monitor precise distances, and provide contactless safety measures in applications ranging from industrial machinery to robotics and consumer electronics.

What’s Inside the Invisible Shield?

The power of an IR Reflectance Alarm lies in its smart design,not in how visible it is. These compact devices are powerful, containing precise components that detect, interpret, and respond to reflected infrared signals. This makes them trusted silent guardians in many industries.

At the core is the Infrared LED. It produces a focused beam of invisible light, which performs reliably in darkness, dust, or smoke. The Photodetector, often a photodiode or phototransistor, captures the reflected IR light. It converts light into electrical signals. This lets the system “see” objects without touching them.

The Signal Processing Unit interprets these signals. It uses algorithms and threshold logic to determine whether an object is within the detection zone. Microcontrollers or DSPs support real-time calibration and sensitivity adjustments.

Optical filters and lenses boost accuracy. They block unwanted light and focus the IR beam. This ensures consistent detection. Protective housings, made of strong polymers or metals, keep electronics safe. They guard against dust, moisture, vibration, and temperature changes. High-end models provide temperature compensation and allow adjustable detection thresholds. Additionally, many models feature communication interfaces for seamless integration into automation systems.

Where do IR Reflectance Alarms Save the Day for You?

IR Reflectance Alarms are single-point versatile sensors that, in several sectors, increase safety, efficiency, and automation. Their uses span across several sectors, including

- Industrial Automation: Detects objects on conveyor belts, prevents collisions, and ensures precise machine operations — reducing downtime and operational hazards.

- Robotics: Enables autonomous navigation, obstacle detection, and collision avoidance in manufacturing and warehousing.

- Security Systems: Serve as invisible sentinels for intrusion detection, perimeter monitoring, and access control.

- Consumer Electronics: Power touchless switches, gesture-controlled devices, and smart appliances for enhanced hygiene and convenience.

- Automotive Applications: Assist in parking sensors, lane detection, and proximity alerts to improve driver safety.

- Healthcare: Support patient monitoring, contactless interfaces, and automated alerts for safer and more efficient care.

- Smart Buildings & IoT: Enable automation in lighting, HVAC, and security systems for energy-efficient, responsive environments.

Why We Trust These Silent Guardians

IR Reflectance Alarms have several benefits that make them a first choice in safety and sensing technologies.

- Non-Contact Operation: Can detect objects and movement without any physical contact; thus, the device is less likely to experience wear, tear, or contamination.

- Reliable Performance in Any Environment: The device performs efficiently even in dark, dusty, or harsh industrial conditions where traditional sensors struggle.

- Fast Response Time: The device’s rapid detection enables prompt alerts and thus, it is able to prevent accidents or the stoppage of operations.

- Energy Efficient: The device can monitor continuously with minimal power consumption

- Compact and Flexible Design: Can be easily placed in/on various types of machinery, robotics, and consumer electronics without interfering with the rest of the parts or components.

- Low Maintenance: Less maintenance work is needed because the parts are durable, and the non-contact operation is a factor as well.

- Cost-Effective Safety Solution: Provides high-level safety without requiring extensive infrastructure or complex setups

- Enhanced Precision: The alarm can accurately detect the presence, distance, and movement; thus, it is less likely to be deceived by false alarms.

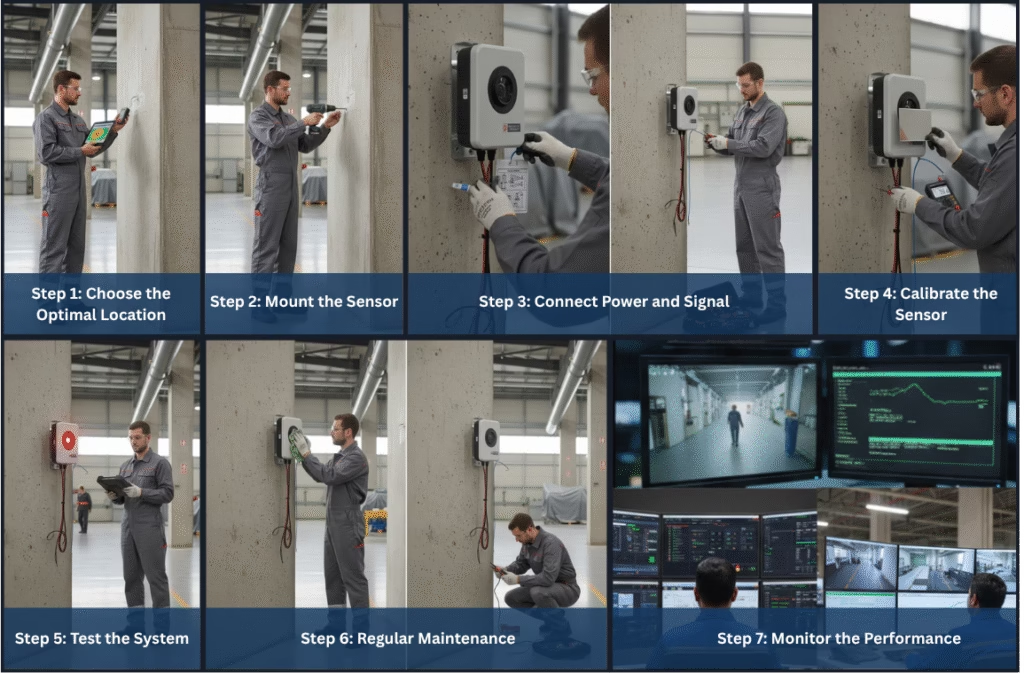

Setting Up Your Invisible Shield: Installation

Installing an IR Reflectance Alarm requires precision but is straightforward with proper guidance.

Step 1: Choose the Optimal Location

Avoid installing the sensor in areas exposed to direct sunlight, near mirrors, or reflective surfaces. Keep it away from strong infrared sources to prevent interference. Ensure the detection field is clear of obstructions.

Step 2: Mount the Sensor

Use appropriate brackets or mounts to secure the device. Prevent mounting the device on vibrating surfaces, as this may cause false alarms or misalignment.

Step 3: Connect Power and Signal

Follow the manufacturer’s wiring specifications. Ensure all connections are stable, correctly insulated, and protected from moisture or mechanical stress.

Step 4: Calibrate the Sensor

Power the unit and test it using typical objects. Sensitivity and point of detection should be changed according to the environment. In different situations, the device must always be able to detect the target.

Step 5: Test the System

Simulate real operating conditions and ensure the alarm functions correctly. Make fine adjustments if necessary.

Step 6: Regular Maintenance

Do not forget to clean the sensor surface from dirt or smudges periodically with a soft, lint-free cloth. Checking the wiring and the connection for any wear or corrosion is also a part of it. If there is a change in the environment or after maintenance, you should recalibrate.

Step 7: Monitor the Performance

Particularly in a crowded place or a heavy industry environment, you should regularly check the system for its security.

Follow these steps, and your IR Reflectance Alarm will be a reliable, hidden protector. It helps keep both people and equipment safe.

Guarding Tomorrow: What’s Next for IR Reflectance Alarms?

IR Reflectance Alarms will play a key role in the future of smart, connected sensing networks. With AI and machine learning, these devices can automatically adjust their settings based on environmental conditions, reducing false alarms and improving accuracy.

Integration with IoT platforms allows real-time monitoring, predictive maintenance, and centralized safety management across industries. Miniaturization and energy-efficient designs are making these sensors suitable for compact devices and wearable technologies. Additionally, expanded detection ranges and multi-spectral IR capabilities promise enhanced performance in challenging conditions.

As automation and smart environments evolve, IR Reflectance Alarms will be indispensable in creating safer, responsive, and truly intelligent systems.

Bringing It All Together: The Path Forward

IR Reflectance Alarms are a perfect example of how invisible tech can bring a very visible change. They deliver exceptional precision, reliability, and safety to different industries. As automation, IoT, and smart systems advance, these silent protectors will be even more indispensable to the safety of people, processes, and assets.

Innovative companies understand that investing in intelligent sensing solutions today paves the way for safer, smarter operations tomorrow. At Syrma SGS, we specialize in designing and manufacturing advanced sensor-based solutions customized to your industry’s needs, ensuring innovation meets reliability. Partner with us to safeguard your future with cutting-edge technology.

Disclaimer: Images used in this Blog are AI generated